Marble Machine

A re-creation of the Wintergatan Marble Machine

Project Documentation

While my Marble Machine and Wintergatan's are veary different, they share the same 7 parts: Frame, Programing Wheel, Lifting Mechanism, Triggering Mechanism, Destributeing Mechanism, Gear Train, and Instuments.

Programing Wheel

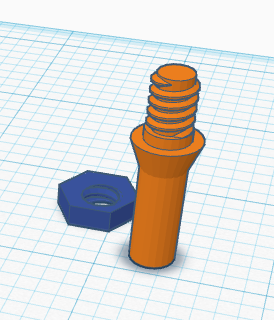

Due to my limited resources there were three key make-or-break hertals in the construction, one of which was the programming wheel. The programming wheel requires over 3000 exactly machened holes, a feet which would take far too long to do manually. For this I used a peg board that I hoped would be flexable enough to strech around a roughly 3-foot wheel. The size and distance apart from the pegboard holes were the determining factor of how large the programming wheel would be; the final design allowed wheel to play 16 measures of music in 4/4 timeing playing only 4th notes. The wheel was cut out of 3/4 in. pine plywood, useing Matthias Wandel's gear generator to genorate the spokes. The cross beams were cut out of scrap wood from our horse pasture fencing. The programming pins were a difficult step because of the thin peg board. Originally, the 3D printed pins were designed to be press fit, but because of the thin board, I had to adjust the model to be threaded, accepting a nut from behind to secure the pin. While this design does make programming the wheel tedious, the pins are very strong and the only concern is that they might be too strong, as I would much rather the pins break rather than take a part of the pegboard with it in the case of it catching on something.

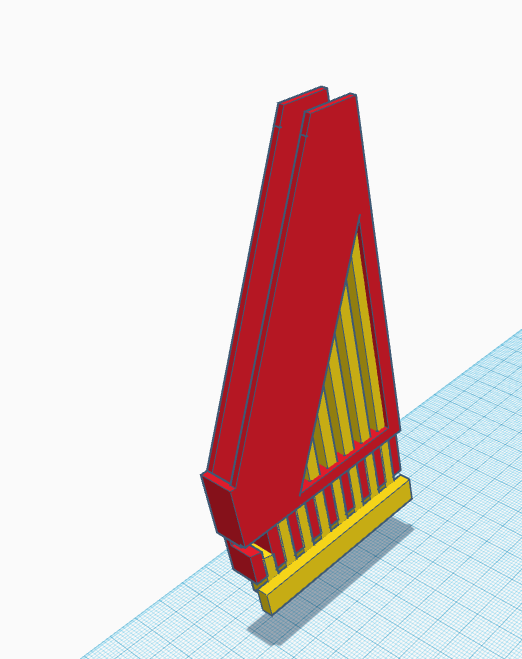

Lifting Mechanism

A fish stair ladder was something I always wanted to incorperate into this prodject, it is a visualy pleaseing way of moveing marbles. The design I decited on is vary different from moast and bypasses the need for a 90 degree gear. 2x4s have always been a simple building block for all of my prodjects and in this module, I hollowed out them to reduce weight. But it was still too heavy and I had to use a supplementary large rubber band to reach an equlebreum, in this way it put the least strain on the gear train.

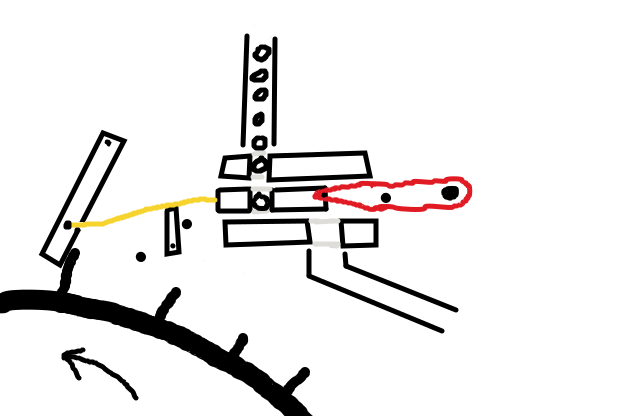

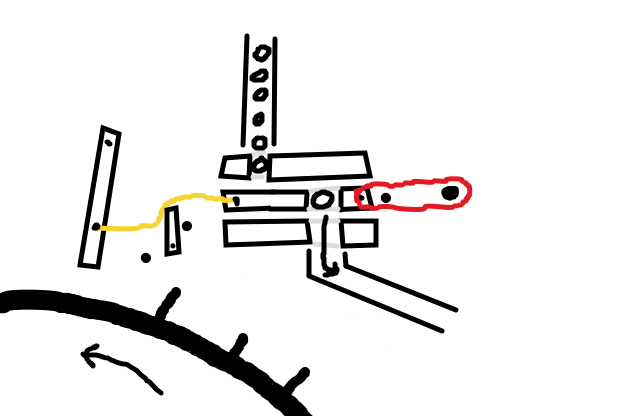

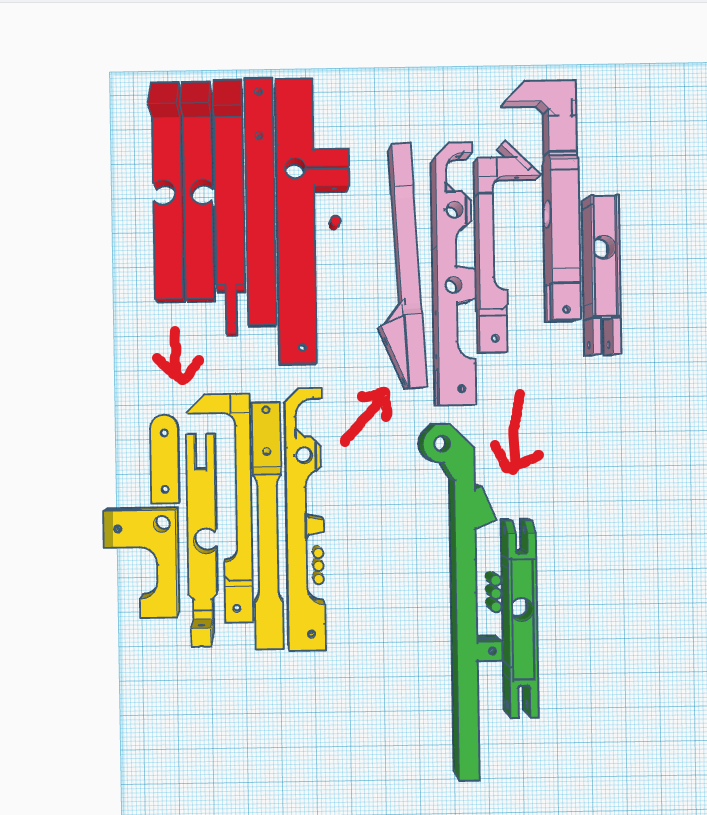

Triggering Mechanism

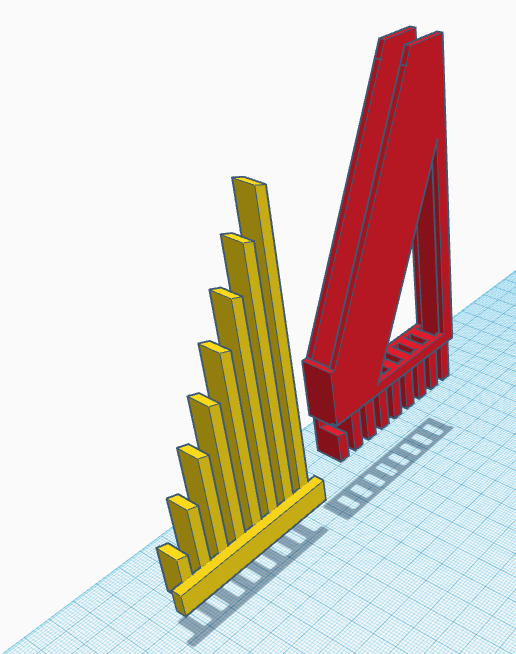

The Triggering Mechanism is the single moast complicated module on this machine, and took the longest time to compelate. It's job is to read the programing wheel and output marbles acordingly and do this in a 100% machanical way. The programing wheel has 24 rows each 1 in. apart, each channel has 9 parts which adds up to 216 parts. On this new machine, a 3d printer was used to automate this prosess.The Muteing Mechanism adds additional complexety to an alrady complex system. For this reason, I decited to compromise and only require the Muteing Mechanism to prefom a whole intument mute, rather than a indavitual instument muteing system. This mechanism operates by rotateing a flap down, allowing the stings connecting each channel together, to go limp.

Triggering Mechanism channel assembly iterations

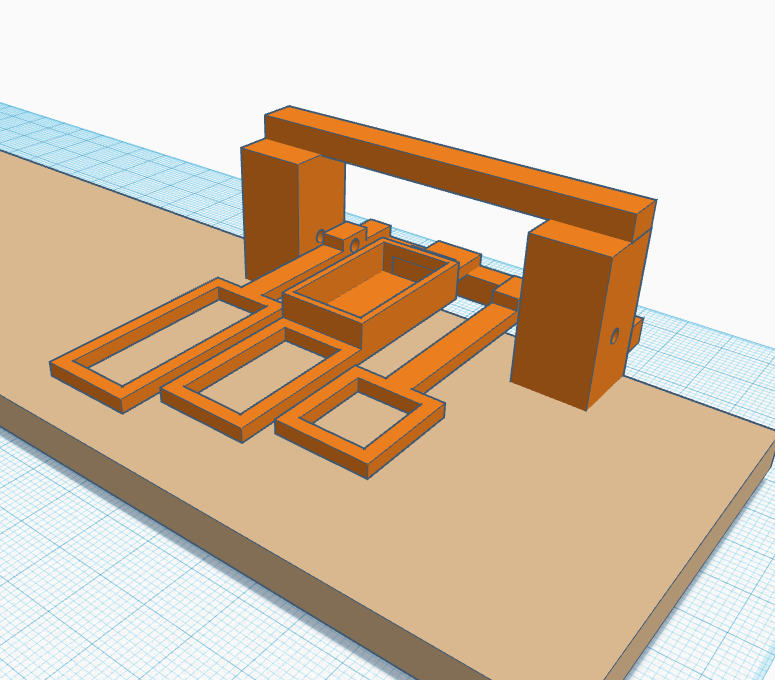

Distibuteing Mechanism

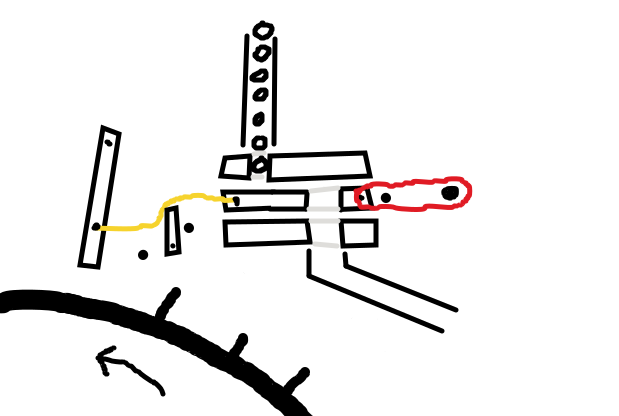

The Distributeing Mechanism sits on top of the Triggering Mechanism and distributes the stream of marbles comeing from the top of the Lifting Mechanism into 24 eaven streams. Initialy my idea was a plinko like system with two extra entry points to counter the natural bell like bias. The design I desided on was the one implemented into the Marble Machine X, which was a long channel with holes along it where marbles would fall down into.

Gear Train

The wooden gear system was anouther make-or-break hurtle in this project, for this I used Matthias Wandel's wooden gear generator. This peice of software allows you to imput number of gears, gear tooth spaceing and more, and then prints out a correctly sized set of papers that when glued together and then onto a peice of wood, serves as a template. There are 7 gears on the Marble Machine, a 20t, 100t, 10t, 128t, 40t, 10t, and 20t. Every gear was also coverd in multiple coats of varnash to help with durabilaty

Instuments

I had to compromise yet again, the instuments I would install on my machine would only be a xilaphone and drums. The instuments would be a xilaphone with 18 changeable notes, a hihat, snare, and kick drum, with 2 chanels each, so they can play twice as fast. The drums constuction consisted of a 3d printed frame, with a sheet of cork and a contact micraphone underneath. The hihat would be thin, the snare with a compartment to house rice, and the kick with a thicker build. The Xilaphone was tricky, as each plate was barely under 1 inch in width, the width of each channel.

Marble Machine History

While I did officialy start this prodject Thanksgiveing day 2017, it has been a vary off and on project. I have build and re-build this machine many times. The first prodotipe of the machine was compeated on Nov. 9th, 2018.

The second prodotipe started April 2020, with a overhauled frame and new much larger programing wheel, this version would take me untill May of 2022 to compleate where it now sits in my garage.